Mineral Insulated Cable

BTTZ Mineral Insulated Cable

According to market demand and improving production efficiency and reducing costs, a mineral fireproof cable model improved on the basis of BTTZ mineral cable makes the production, installation, laying and use of fireproof cables more convenient and closer to practical applications.

BTTW insulated cable, also known as copper sheathed corrugated inorganic insulated cable, is a fireproof cable with copper sheath, which has strong flexibility and strong impact resistance. BTTW insulated cable has its value, because it is a new type of fireproof cable that has been improved on the basis of the drawbacks of BTTZ mineral insulated cable. With the continuous promotion of this product, its excellent performance is more and more recognized by customers, and it is now widely used in basic industry and civil construction.

BTTW insulated cable features:

1. The conductor of BTTW insulated cable metal sheathed inorganic mineral insulated power cable adopts multi-strand copper stranded wire, the insulation is mechanically wrapped with high temperature resistant synthetic mica tape, the insulating layer is densely filled with alkali-free glass fiber, and the sheath is made of copper tape longitudinally. After wrapping, it is welded into a copper tube, and then corrugated by continuous rolling. For specific requirements that the metal sheath cannot be exposed, a layer of polyolefin (low smoke and halogen free) sheath can be added on the outside.

2. Compared with the BTTZ series, while maintaining a high degree of fire resistance, it can achieve continuous large lengths. It can also be made into multi-core group cables within 95mm, which overcomes the shortcomings of too many connectors and too much construction difficulty. . However, the welding seam of the corrugated copper pipe is easy to crack and the single mica insulation has also become a congenital structural defect. The requirements for the installation process capability are still very high. Yuejiaxin wire and cable has also invested a lot of money in research and development to overcome these drawbacks.

3. Excellent fire performance, the fire resistance grade not only meets the national standard GB12666.6A class 950℃, 90min, but also meets the requirements of British BS6387-1994 for A class 650℃3h; B class 750℃3h; C class 950℃3h requirements; , It can also withstand water spray and mechanical impact during combustion.

4. Long continuous length, whether it is a single-core or multi-core cable, its length can meet the needs of the power supply length, and each continuous length can reach more than 1000m.

5. Large cross-section, single-core cable cross-section can reach 630mm2, multi-core cable can reach 70mm2; 4. It is flexible, the cable can be coiled on the coil, and its bending radius is 6-10D.

6. It is smokeless and non-toxic when burning, and the insulation is made of inorganic materials. It will not produce any harmful gas when burning, and will not cause secondary pollution. It is a truly environmentally friendly green product. 6. Large overload capacity, the cable not only has a large current carrying capacity, but also has a large overload capacity. According to the wiring instructions, the surface temperature of the cable is usually less than or equal to 70 °C. If the wiring cannot be touched or contacted with combustible building materials, the temperature of the cable sheath can be increased to 105 °C. When overloaded, the long-term working temperature of the fireproof cable can reach 250 ℃.

7. Corrosion resistance, good shielding performance, and good corrosion resistance of copper sheath. In special or corrosive environments to copper, a layer of low-smoke halogen-free or plastic outer sheath should be added to the copper sheath. Under the shielding of the copper sheath, there is no electromagnetic interference, and it will not interfere with the information transmitted by the signal and control cable.

8. Good safety, the fireproof cable can supply power normally in the flame (normal power supply for more than 3 hours at 950℃), start the fire extinguishing device, and reduce the fire loss. The copper sheath is an excellent conductor and a good grounding wire, which greatly improves the sensitivity and reliability of grounding protection.

9. Long service life, high temperature resistance and not easy to age. Under normal working conditions, its service life is more than 100 years.

10. The transportation, installation and installation accessories of the flexible fireproof cable are relatively simple, similar to ordinary cables.

11. Good economy. Due to the advanced production technology and simple installation, the comprehensive cost of the flexible fireproof cable is lower than that of the mineral insulated cable under the same conditions.

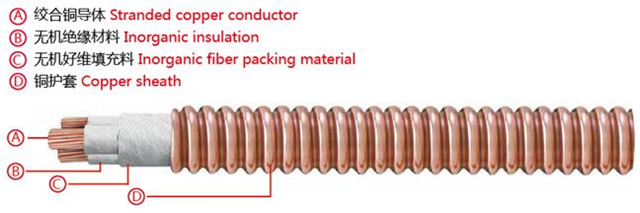

Example 1: BTTW insulated cable structure diagram BTTW picture

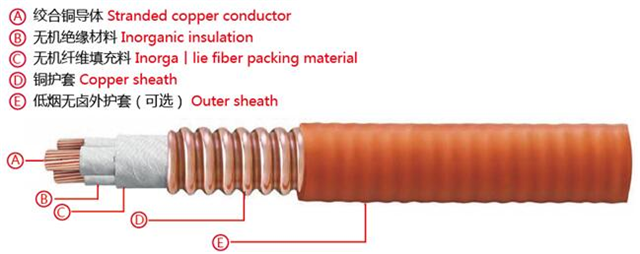

Example 2: WD-BTTWY structure diagram WD-BTTWY structure diagram

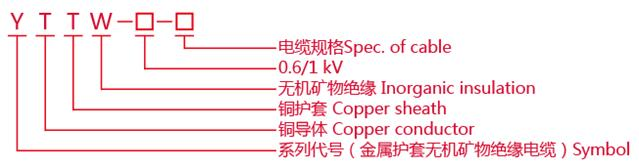

Example 3: BTTW flexible mineral insulated cable model specification

Fire resistance characteristics of BTTW flexible fireproof cable:

1. According to the national standard, the fire resistance test method of wire and cable combustion test method GB/T 19216.21-2003 selects the flame temperature of 950 ℃ ~ 1000 ℃, the burning time is 180min, and the line is kept intact.

2. According to the British BS6378 standard, the flexible fireproof cable can meet the following requirements: pure fire resistance class C: 950℃ 180min; fire resistance plus water class W: 650℃ 15min; fire resistance plus mechanical vibration Z class: 950℃ 15min (the above tests are in the same order root test).

The test report of the National Wire and Cable Supervision and Inspection Center for BTTW flexible mineral insulated fireproof cable passed the British bs6387 fire resistance standard.

Electrical characteristics of BTTW insulated cables:

1. Rated voltage: 0.6/1kV;

2. Rated working voltage: light load 500V, heavy load 750V:

3. Rated current: single-core 25A-1800A, multi-core 16A-500A;

4. Insulation resistance: Insulation resistance>1000MΩ·km. If the cable length is less than 100m, the insulation resistance is greater than 10000MΩ;

5. Power frequency withstand voltage: 500V class cable and 750V class cable respectively apply 2000V and 2500V voltage between phase and phase, phase and copper sheath for 15min, no breakdown should occur.

BTTW flexible fireproof cable manufacturing standard JG/T 313-2014 People's Republic of China construction industry industry standard "Rated voltage 0.6/1kV and below metal sheathed inorganic mineral insulated cables and terminals". There have been some bad manufacturers on the market that use copper tape interlocking armor to counterfeit BTTW arc welding threaded copper sheath. The main point is that it cannot be waterproof, it is easy to be short-circuited by moisture, and it cannot pass the spray fire test of the British standard BS 6387. The comprehensive performance is worse than that of ordinary cables. Yuejiaxin Wire and Cable provides users with better quality and safer fireproof cables through unremitting innovation and scientific research investment to ensure the normal energization of electricity.Yuejiaxin Wire and Cable has 20 years of experience in the cable industry and has introduced advanced foreign technology and equipment. Provide one-stop solutions and technical support.