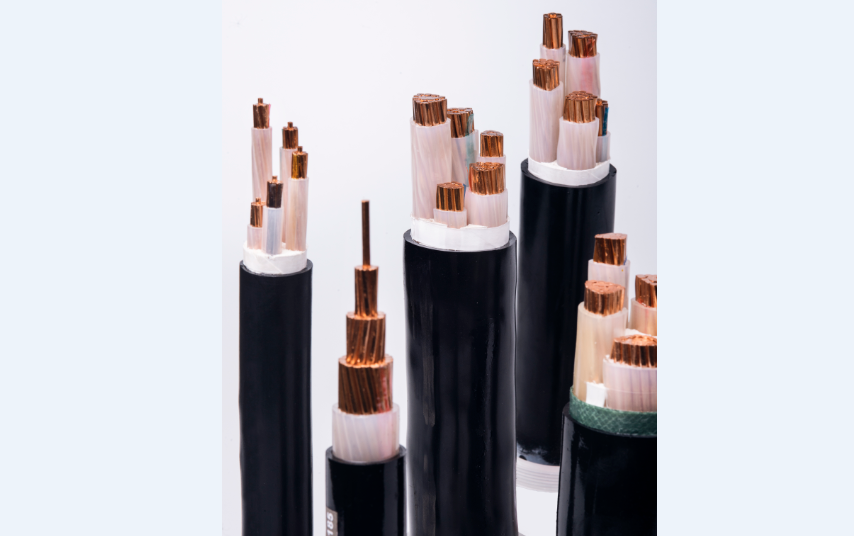

LOW Smoke Zero Halogen (LSZH) Cables

After technological innovation, Yuejiaxin Cable has continuously improved the low-smoke halogen-free cable and enhanced its function. The produced low smoke zero halogen cable does not contain any halogen and other toxic substances, and there is no excess smoke in the case of incineration. When a fire occurs, the extension speed is slow, the smoke concentration is low, the visibility is high, and the release of harmful gases is small, which is convenient for personnel to evacuate. The corrosiveness of the incineration gas is small, and it also avoids the harm to the equipment. The characteristics of low halogen and halogen-free make the cable material greatly improve the aging resistance, ultraviolet resistance and other irradiation functions, and extend the service life of the cable. The following Yuejiaxin company summarizes its various characteristics for everyone:

1. No toxic black smoke will occur during burning (a small amount of white smoke will occur);

2. The characteristics of LSZH cables - the tensile strength is greater than that of ordinary PVC wires: the tensile strength of general PVC cable is greater than 1.05Kgf/mm², while the tensile strength of low-smoke halogen-free wires is greater than 1.2Kgf/mm²;

3. The characteristics of LSZH cables - excellent weather resistance (-30℃~105℃); excellent softness (hardness: 80-90);

4. The characteristics of LSZH cables - non-migration (because there is no need to add plasticizers in this product formula, so there will be no migration);

5. High volume resistivity: PVC wires are generally 1012~1015Ω/cm³, and low-smoke halogen-free wires are greater than 1016Ω/cm³; they have excellent high-voltage resistance characteristics;

So, what are the identification methods of low-smoke halogen-free wires?

1. Skin burning method:

There should be no significant depressions in the insulating layer by ironing it with an electric iron. If there are large depressions, it means that there are shortcomings in the materials or processes used for the insulating layer. Ignite with a lighter. Under normal circumstances, it should not be easy to light. After long-term incineration, the insulation layer of the cable is still relatively intact, there is no thick smoke and irritating odor, and the diameter has increased. The low-smoke halogen-free wire with flame retardant function will burn even if It will also subside in a while, preventing the fire from spreading. If it is easy to light, it can be confirmed that the insulation layer of the cable is not made of low-smoke halogen-free material (probably polyethylene or cross-linked polyethylene material). If there is a large amount of smoke, it means that the insulating layer is made of halogen-containing materials. Jinlianyu cable WDZB-BYJ(F)-105 product adopts irradiation cross-linked low-smoke halogen-free material, which has excellent environmental protection, less burning smoke and no toxic gas.

2. Hot water immersion method:

Soak the core or cable in hot water at 90°C. Under normal circumstances, the insulation resistance will not drop rapidly and remain above 0.1MΩ/Km. If the insulation resistance drops sharply or even lowers than 0.009MΩ/Km, it means that it has not undergone proper irradiation cross-linking process.

3. Density comparison method:

Low-smoke halogen-free material is denser than water, peel off a small amount of insulating layer and put it in water. If it floats above the water surface, it must not be a low-smoke halogen-free material.

Yuejiaxin produces cables : PVC cable , XLPE calbe. Electric cable ,powe cable, LV cable ...