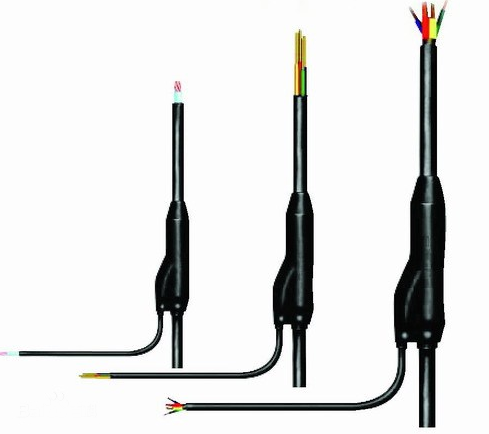

Pre-branch Cable

What is a prefabricated branch cable

The pre-branch cable is a cable that prefabricates branch lines according to the user's design drawings when the factory produces the main cable. It is a new technology product in recent years. The branch line is pre-fabricated on the trunk cable by the factory. The cross-section size and branch line length of the branch line are determined according to the design requirements, which greatly shortens the construction period, greatly reduces the material cost and construction cost, and ensures the safety of power distribution. sturdiness and reliability.

Specifications and Requirements

1) Technical requirements for cable inspection:

a. The main and branch cables should comply with GB5023.1-1997; GB5023.2-1997; GB5023.3-1997; GB5023.4-1997; GB5023.7-1997 "rated voltage 450/750V and below PVC insulation Cable" and IEC227-1; IEC227-2; IEC227-3; IEC227-4; IEC227-7 related technical indicators and requirements.

b. The main and branch cables should meet the specifications, models and cross-section requirements specified by the user.

2) The cable hanger is used as a lifting device for prefabricated branch cables in vertical installation and arrangement, and is an accessory of prefabricated branch cables. In horizontal arrangement, this accessory is not required.

skills requirement:

a. Withstand AC.3500V, 5min without breakdown; insulation resistance ≥200MΩ.

b. The prefabricated branch cable will not fall off for 24h under the gravity of 2 times its own weight. After the prefabricated branch cable is installed and fixed, the lifting head no longer bears gravity.

3) Technical requirements for stripping the outer sheath and inner insulation of the main and sub-cables:

a. Confirm the length and size specified by the user;

b. The outer sheath and inner insulation of the main and sub-cable should be cut neatly, and the conductor material of the cable should not be damaged.

4) Technical requirements for press forming of branch joints:

a. The joints should meet the requirements of technical standards;

b. The branch joint after crimping should have sufficient crimping force and contact area to ensure that the contact resistance is about the resistance of the equivalent length conductor;

C. It is not allowed to damage the conductor materials of the main and sub-cables during the crimping process;

5) Technical requirements for injection molding of branch joints:

a. The insulating material used for injection molding shall be the same as that of the inner insulation or outer sheath of the main and sub-cables;

b. Do not cause any damage to the original inner insulation and outer sheath of the main and branch cables during the injection molding process;

c. Ensure the air tightness and water tightness after the injection molding material and the outer sheath of the main and sub-cable are effectively adhered;

d. After the injection molding of the branch conjoined body, the withstand voltage AC.3500V, 5min does not appear breakdown; the insulation resistance is ≥200MΩ.

6) Finished product inspection of prefabricated branch cables

a. Visual inspection;

b. Continuity inspection of main and branch cables;

c. Withstand voltage test;

d. Insulation resistance inspection.

7) Finished packaging of prefabricated branch cables

The prefabricated branch cables are packaged to seal each cable end with a cable cap, then wound on a cable reel or bundled, and packaged in a suitable way that will not damage the cable during transportation.

Yuejiaxin produces cables: PVC cable, XLPE cable,electric cable,power cable, LV cable